In precision robot manufacturing processes, ultra precision machining operations such as chamfering and rounding are characterized by relatively low contact forces and low material removal. For this process, traditional automation methods such as pre programmed position or force control, without adjustment, are not suitable for achieving high-precision surface finishing. Therefore, the polishing work is still mainly completed manually by skilled operators.

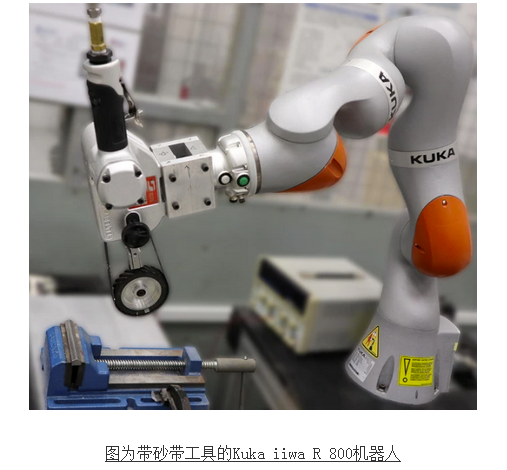

In this study, researchers proposed an adaptive framework that can polish a wide range of materials, including hard metals such as titanium, using collaborative robots. Researchers have proposed an iterative learning controller based on impedance control, which adjusts the position and force simultaneously during each iteration to adjust the polishing process. The proposed controller can track the required contour without any prior knowledge of the forces required to polish different materials.

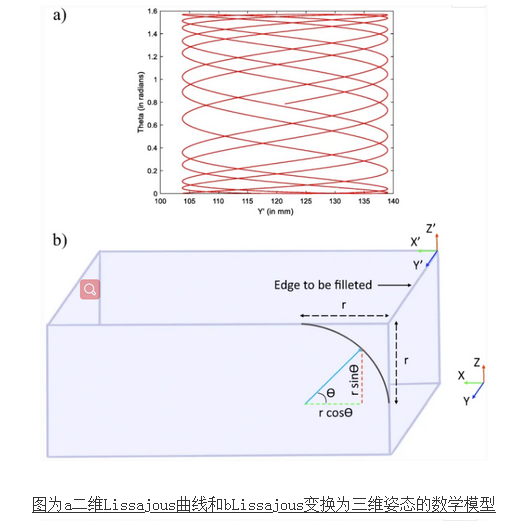

In addition, researchers have proposed a new mathematical model for generating complex rounded tool trajectories based on Lissajous curves. Experiments were conducted using a collaborative industrial robot to validate the new framework in completing tasks such as chamfering and slicing. Surface roughness and contour measurements indicate that the researchers' adaptive controller can achieve good polishing output on various materials such as titanium, aluminum, and wood. This article is titled "An adaptive framework for robotic polishing based on impact control" and was published in The International Journal of Advanced Manufacturing Technology magazine on November 20, 2020.

Super polishing robot, super precision!

Research background and experiments

The research on robots has made significant progress in industrial applications such as painting, palletizing, and welding. Due to the negligible interaction between the end effector and the environment, these tasks can be executed using simple position based or force based control strategies. Although there have been many advancements in robotics technology, tasks involving physical interaction with environments that humans excel in pose inherent challenges to robot autonomous execution.

The subtle position and force adaptation exhibited by human operators to compensate for instability cannot be captured solely through pre programmed position or force control strategies. Therefore, polishing tasks that account for 50% of the total manufacturing time in the industry still rely mainly on skilled operators. Despite growth, robot sorting accounts for less than 1% of current robot applications.

This is due to several factors, such as the fact that robot metal processing still lacks surface smoothness and accuracy compared to manual operations, as well as the programming difficulties of the robot itself. When it comes to small and medium-sized enterprises (SMEs), these issues worsen because they handle high mix and low batch parts. Robots used for polishing require a high degree of compliance during the execution process to control the final output. Therefore, an adaptive interactive control is needed to achieve the desired contour geometry and surface roughness, which can be achieved through special compliance tools such as macro micro systems or compliance based on control algorithms.

In interactive control using special compliant tools, end effectors can usually compensate for force errors on different axes. Flexible tools can be passive or active to maintain the required contact force. Passive flexible tools typically rely on the compliance of the tool itself to maintain normal contact force, while active flexible tools rely on closed-loop force control systems to correct force errors.

In addition, excessive tool compliance will reduce the stiffness during polishing and reduce the accuracy of contour tracking. In order to implement interactive tasks using control algorithms, hybrid position and force controllers or impedance controllers are typically deployed. In the mixed position and force control of surface finishing, the position is usually adjusted along the surface, while the force is usually controlled in the normal direction. The force control strategy and hybrid position and force control of robotic arms have been widely applied, including deburring and polishing

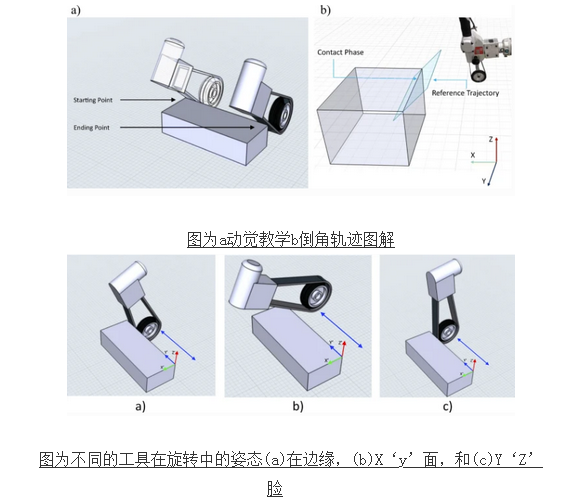

The figure shows the posture of different tools during rotation (a) at the edge, (b) on the X 'y' face, and (c) on the Y 'Z' face

Super polishing robot, super fine, polishing like new!

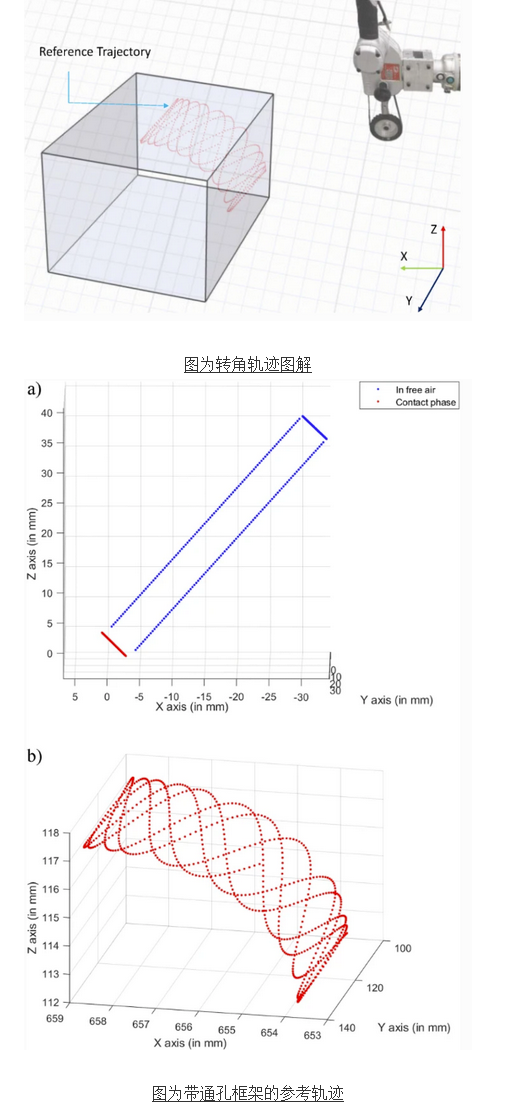

Feedback information about the actual position, force, and direction of the robot reaching any specific point is recorded and stored in the analysis. At the end of each iteration, compare the actual trajectory obtained by the controller with the reference trajectory in the equation. This incremental trajectory adjustment is to ensure that the finishing operation is completed according to the expected contour and incremental force adjustment without damaging the workpiece. In addition, due to error correction through iterative feedback, the loop also reduces the amount of rework in the future.

Researchers conducted chamfering experiments on aluminum processing coupons using the same arm end tool and observed the same control behavior as the titanium experiment. After inputting commands and studying the device, it was found that after 13 passes, the position error no longer significantly decreased and reached the saturation point shown in the absolute error diagram. Compared to the titanium experiment, the aluminum content is relatively low. Therefore, the average force observed during each iteration is often lower than the average force observed during the titanium experiment described in the figure. Due to the much lower hardness of aluminum compared to titanium, the actual trajectory of the robot can relatively quickly approach the expected reference trajectory during the initial iteration, resulting in lower force on the robot's subsequent pass. Greatly enhanced design performance!

Copyright @ 2023 Yuzhun Precision Machinery (Shanghai) Co., Ltd. All Reserved 沪ICP备17049184号-2